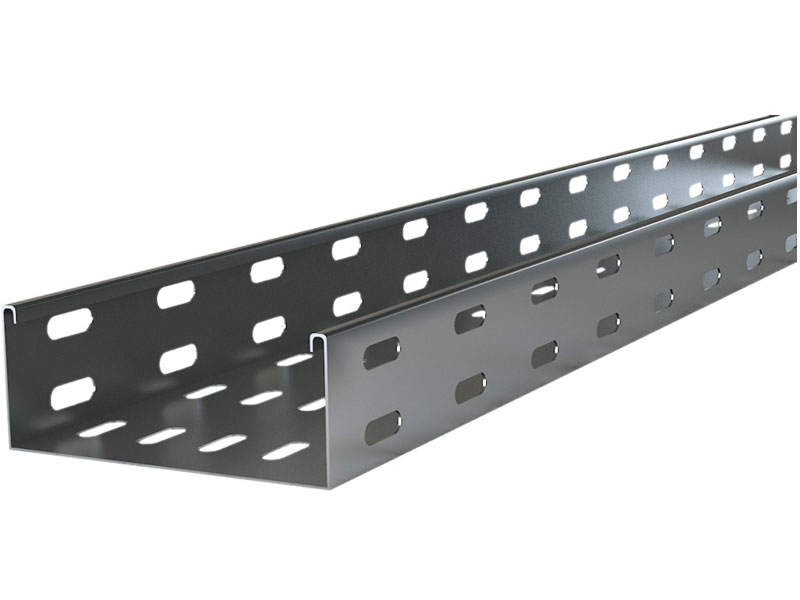

Cable Tray

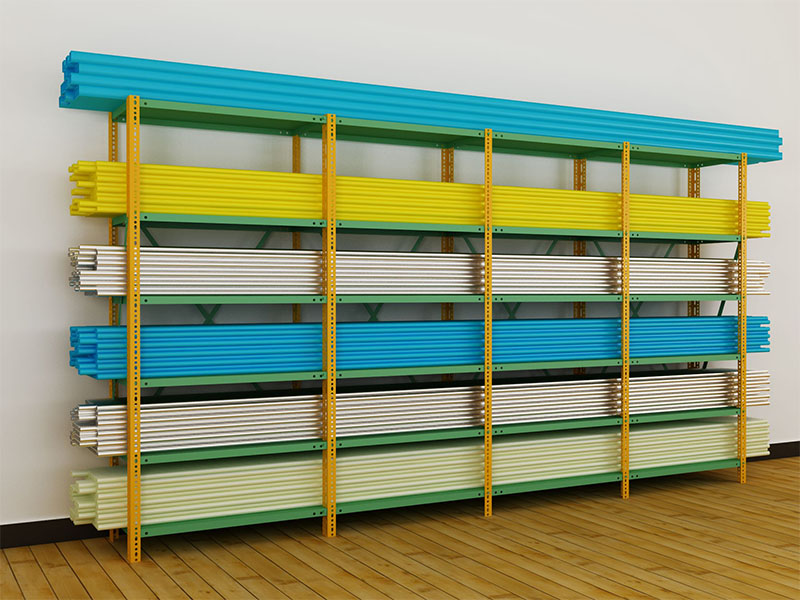

- Cable tray is a rigid structural support system used to securely fasten or support cables. In the electrical wiring of buildings, a cable tray system is used to support insulated electric cables used for power distribution and communication

- Because a cable tray wiring system provides safe and dependable ways to save now and then

- Cable tray wiring systems are the preferred wiring system when they are evaluated against equivalent conduit wiring systems as cable trays are less expensive, more reliable, more adaptable to changing needs and easier to maintain. In addition, their design does not contribute to potential safety problems associated with other wiring systems

A properly engineered and installed cable tray wiring system provides some highly desirable safety features that are not obtainable with a conduit wiring system including:

- Tray cables do not provide a significant path for the transmission of corrosive, explosive, or toxic gases while conduits do

- In addition to explosive gases, corrosive gases and toxic gases, failures can travel through the conduits to equipment or control rooms where the plant personnel and the sensitive equipment will be exposed to the gases

- In facilities where cable tray may be used as the equipment grounding conductor, the grounding equipment system components lend themselves to visual inspection as well as electrical continuity checks

- Cable tray provides a wiring system of outstanding dependability for the control, communication, data handling, instrumentation, and power systems. The dependability of cable tray wiring systems has been proven by a 40 years track record of excellent performance

- Cable tray wiring systems have an outstanding record for dependable service in industry. It is the most common industrial wiring system in Europe. In continuous process systems, an electrical system failure can cost millions of dollars and present serious process safety problems for the facility, its personnel and the people in the surrounding communities

- A properly designed and installed cable tray system with the appropriate cable type will provide a wiring system of outstanding dependability for process plants

- Television broadcast origination facilities and studios make use of cable tray to support and route the large volumes of cable needed for their operations with a high degree of dependability. It would be impossible to have the wiring system flexibility they need with a conduit wiring system

- Large retail and warehouse installations use cable tray to support their data communication cable systems. Such systems must be dependable so that there are no outages of their continuous inventory control systems

- Cable tray wiring systems have been widely used to support cabling in both commercial and industrial computer rooms overhead and beneath the floor to provide orderly paths to house and support the cabling. These types of installations need a high degree of dependability, which can be obtained using cable tray wiring systems

- When compared to a conduit wiring system, an equivalent cable tray wiring system installation requires substantially less space

- Large conduit banks require significant space, competing with other systems and equipment. Choosing a cable tray wiring system greatly reduces this problem

- Financial institutions with large computer installations have high density wiring systems under floors or in overhead plenum areas that are best handled by cable tray wiring systems

- Airport facilities have extensive cable tray wiring systems to handle the ever expanding needs of the airline industry

- Cable tray is used in many facilities (e.g. factories, corporations) because of the ever present need of routing more and more cables in less space at lower costs

- Large health care facilities have high density wiring systems that are ideal candidates for cable tray

- Over the past decades the results of cost evaluation studies have proved that the installed cable tray wiring system will cost 10 to 60 percent less than an equivalent conduit wiring system. As the installed cable trays tend to reduce engineering costs, maintenance costs, and production losses due to power outages

- For projects that are not 100% defined at the engineering and drafting design phases, the cost of and time used to apply continuous changes will be substantially less for cable tray wiring systems than for conduit wiring. As a small amount of engineering is required to change the width of a cable tray or to gain additional wiring space capacity

- The fact that a cable can easily enter and exit cable tray anywhere along its route, allows for some unique opportunities that provide highly flexible designs

- Excluding conductors, the cost of the cable trays, supports, and miscellaneous materials will provide a savings of up to 80% as compared to the cost of the conduits, supports, pull boxes, and miscellaneous materials

- Depending on the complexity and magnitude of the wiring system, the total cost savings for the initial installation (labor, equipment and material) may be up to 75% for a cable tray wiring system over a conduit wiring system

- For large conductors, pull or junction boxes may be required more often to facilitate the conductor’s installation. Cable tray wiring systems do not require pull boxes or splice boxes

- Penetrating a masonry wall with cable tray requires a smaller hole and limited repair work

- One of the most important features of cable tray is that tray cable can easily be installed in existing trays if there is space available

- Tray cables do not provide internal moisture paths as do conduits. Thereby, electrical equipment and material failures could be avoided.

- Metallic cable trays are readily available in aluminum, Pre-galvanized steel, hot-dip galvanized after fabrication, and stainless steel. Aluminum cable tray should be used for most installations unless specific corrosion problems prohibit its use. Aluminum’s light weight significantly reduces the cost of installation when compared to steel

- Cable trays are either installed in the ceiling (using stud bolts), in the wall or on the floor

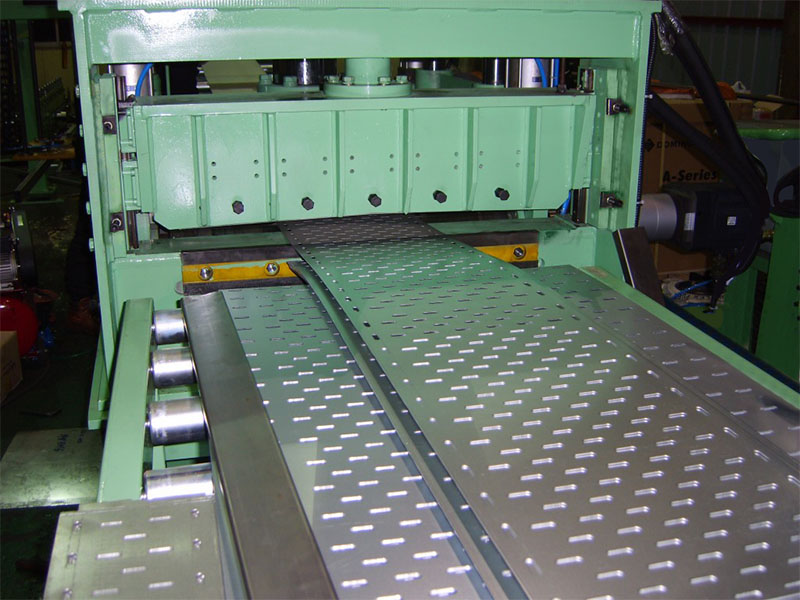

- Cables are made of galvanized sheet, stainless steel, coated sheet or wire with a 0.8 mm to 2.0 mm thickness

- Cable tray is provided with many accessories and components including the cover, connections, joints and angles

- One of the functions of cable tray is to protect the electrical cables that feed main switchgear, sub-panels and lighting

- Cable trays can be used in a variety of settings as they can be rated for outdoors; indoors; corrosive and classified hazardous locations; and areas with high electrical noise and vibration such as, factories, commercial buildings, train stations, big corporations, and many other locations

Request a quote

Protducts Categories

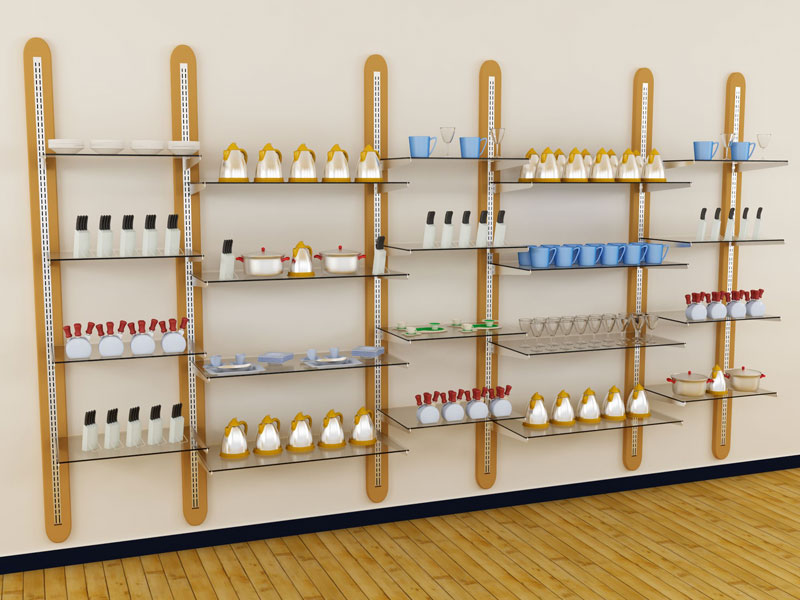

- Shop Display & Fitting Systems

- C Punched Column System

- Cable System

- Connector

- Drawers System

- Stainless Steel Drawers

- Exhibition System

- Four Punched Sides System

- Global System

- Gondola System A

- Gondola System B

- Joker Systems

- Ladder System

- Line System

- Linear system

- Primo System

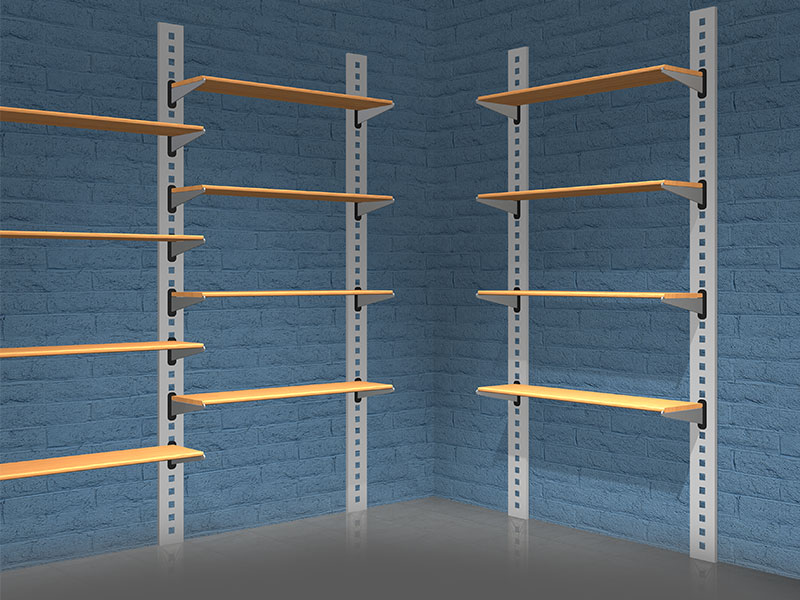

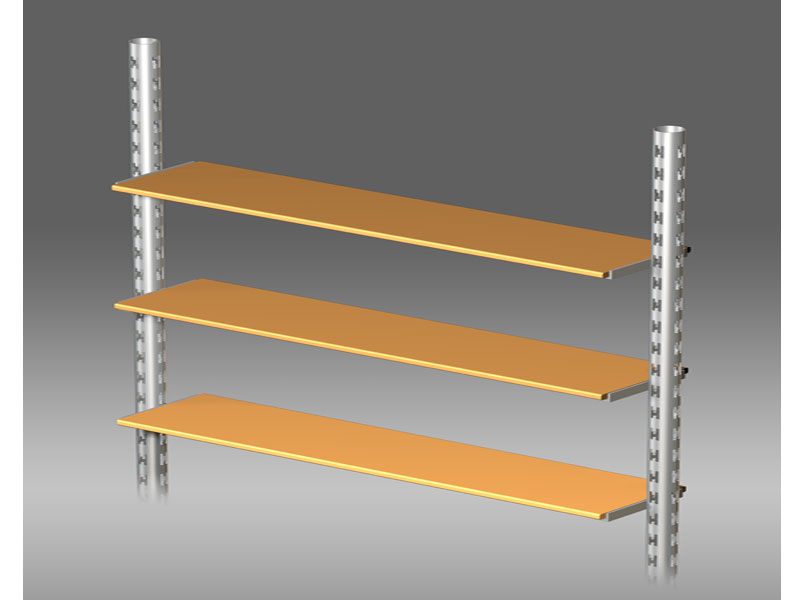

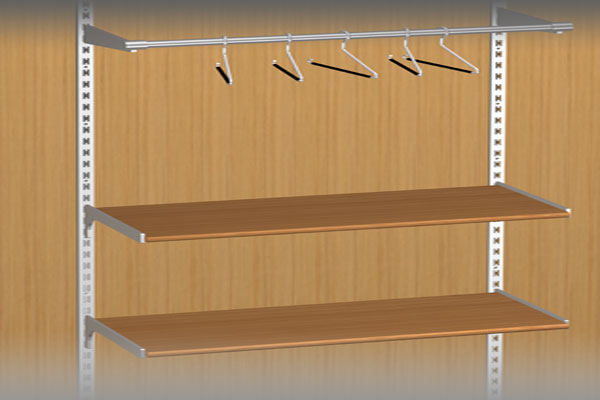

- Punched Wall System

- Rectangular Tubes

- Roto System

- Round System

- Sail System

- Shopping Baskets & Trolleys

- Slat Grid System (Mesh grid)

- Slat Wall System

- Slotted Tube System

- Squared 25 System

- Standard System

- Tubing system

- U Shape System

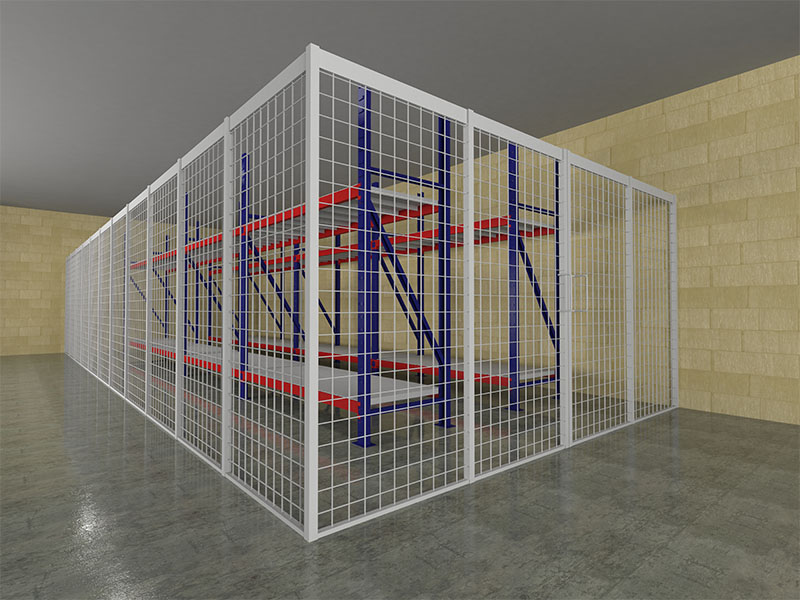

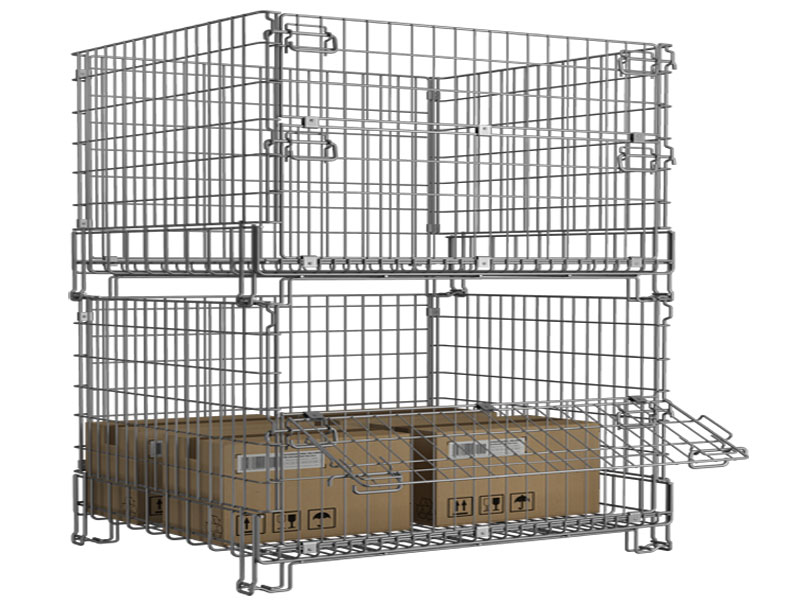

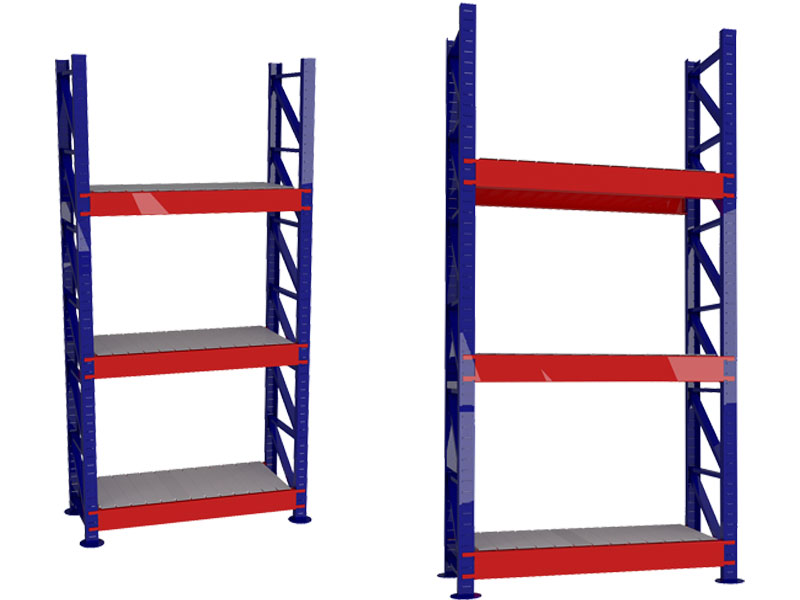

- Storage & Racking Systems

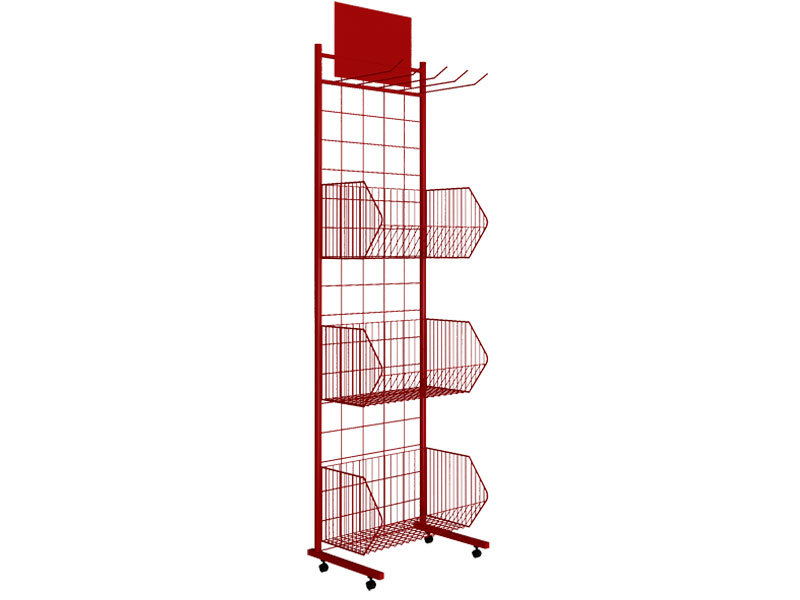

- Display Stands

- Decorative Stainless Steel Works

- Metal Furniture

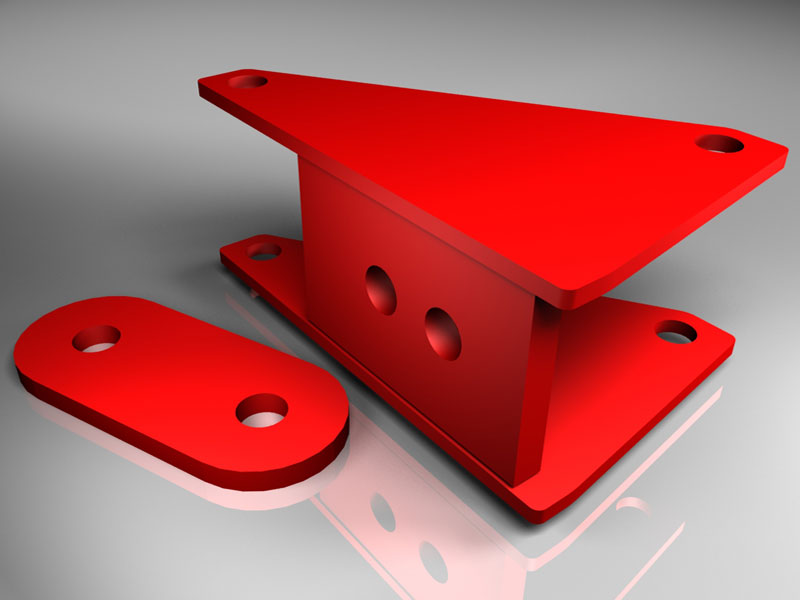

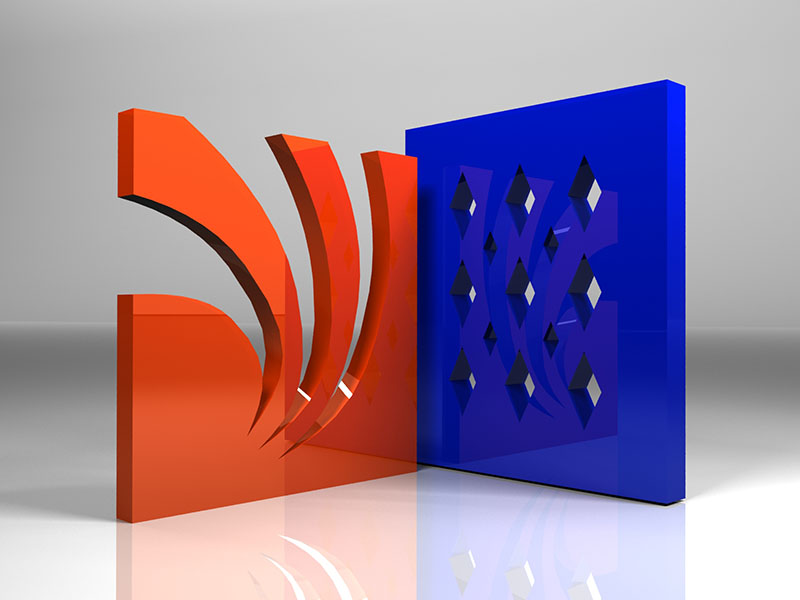

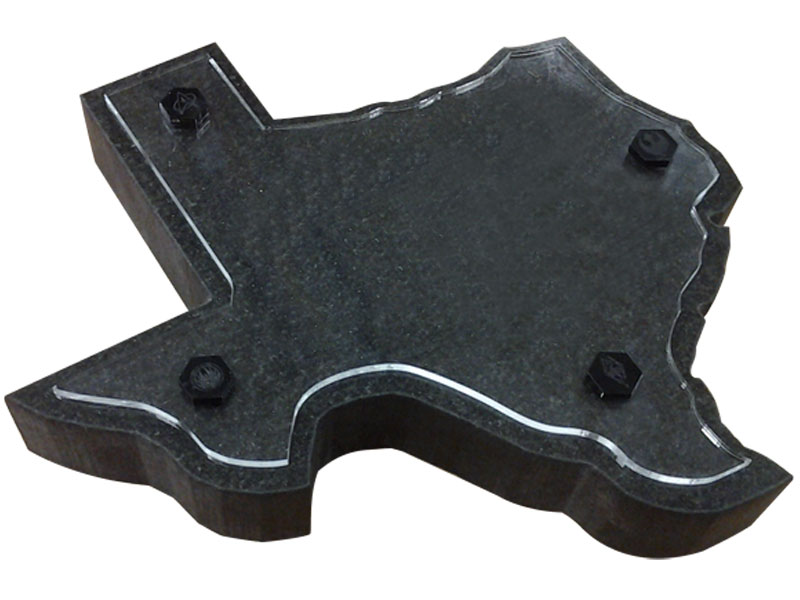

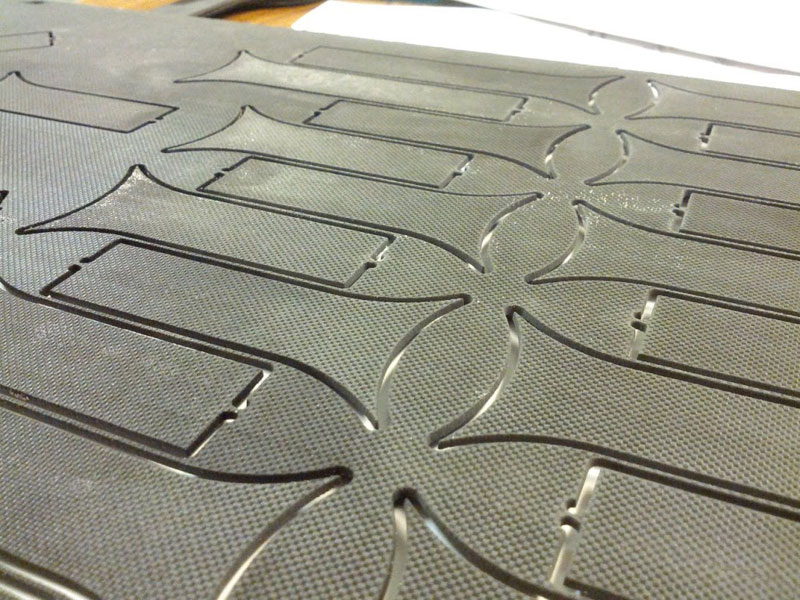

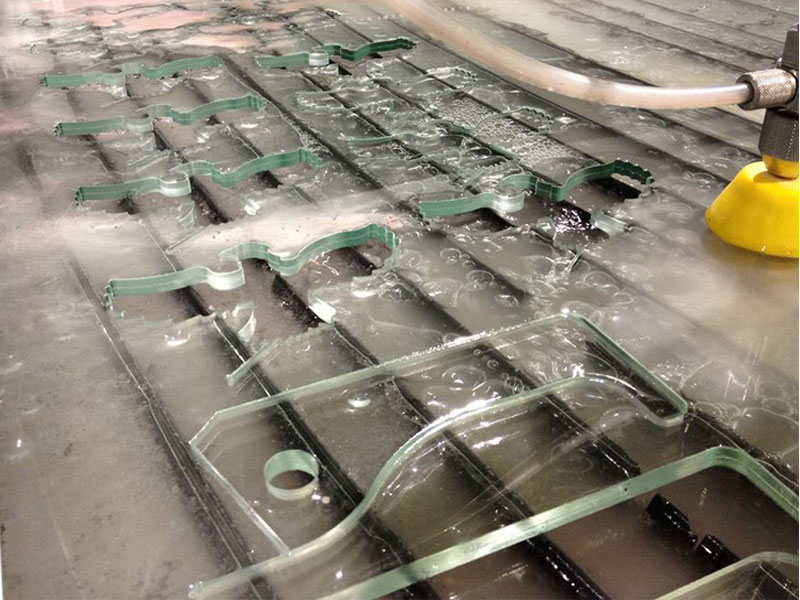

- WaterJet Cutting Applications

- New Customized Solutions

- Flexible Rack system

- Stainless Steel Drawers

- Storage x Gondola System

- British Gondola System

- Mold Table

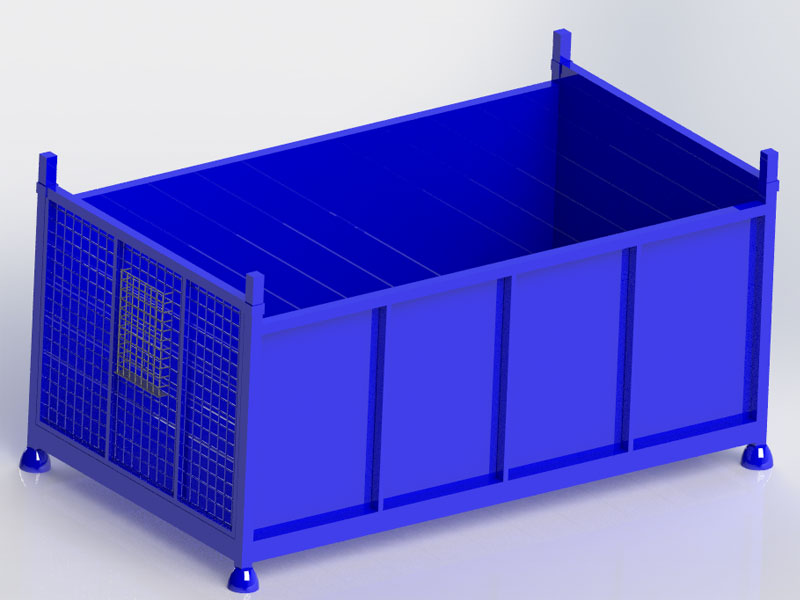

- Trundle for Storing Boxes

- Roll Holder

- Snacks Display Stand

- Archive Gondola System

- Punched Gondola

- Gold Plated Columns

- Islamic Design Door

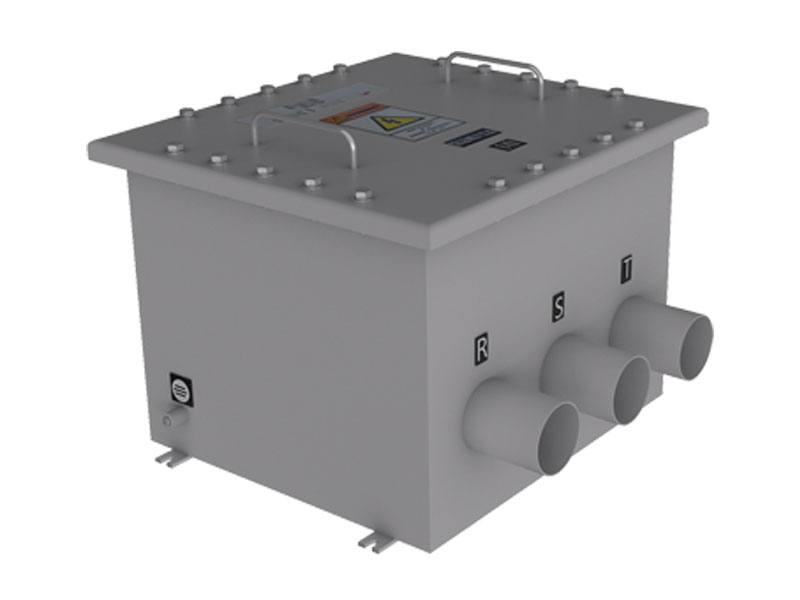

- Protective Electrical Boxes

- Customized Heavy Duty Unit

- Gondola with Wire Bars