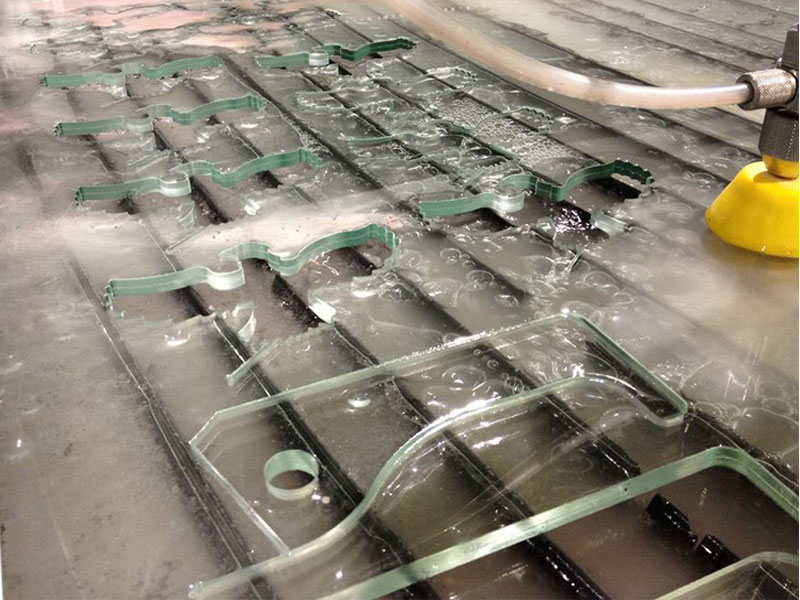

The coating lines depend mainly on the presence of products with very clean surfaces, therefore, the grease and rust on products` surfaces must be removed in order to get these clean surfaces. Then a chemical material is added on the surface, which works on the adhesion of the powder or the coating powder with the product. As the presence of this material on the product surface works on the interaction between sheet and powder inside the furnace, and finally leads to the robust cohesion between the powder and the ore or the product that needs to be coated

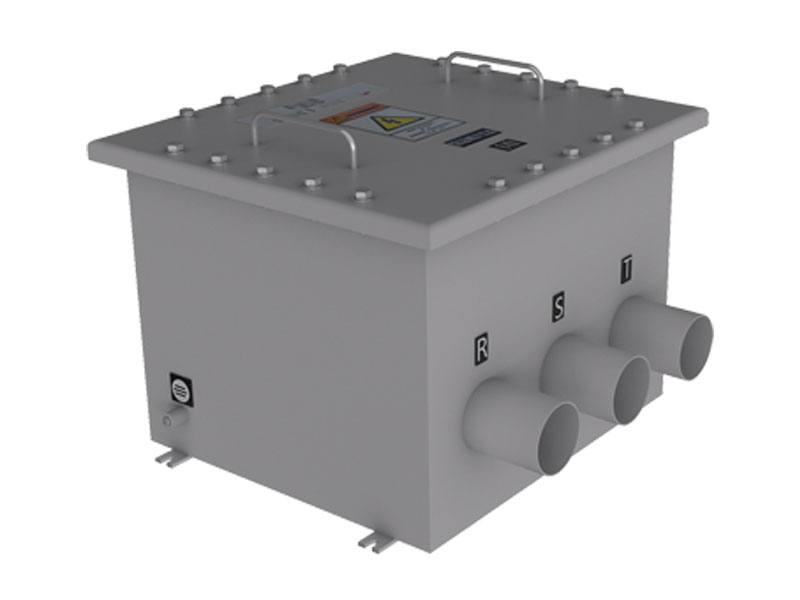

In addition, one of the most important priorities in paints is to regulate the furnace temperature and the time used for products` coating and cooling, and the concentration of acids. Otherwise, the result of paints will be very bad, if there is any disorganization of any of these elements. Moreover, a good test for paints is done after products coating. For example, paint thickness on the metal is ranging from 60 to 80 microns for powder and 10 to 15 microns for nickel. If these elements were available, paints will be excellent

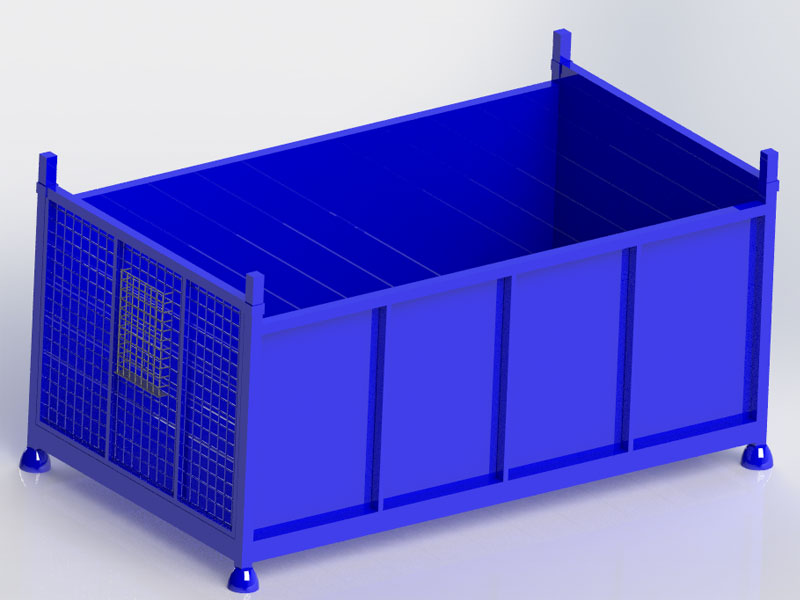

In addition, the choice of material types such as sheet (Cold Rolled, Hot Rolled, pickled, or galvanized) affects the paints. For example, our choice of the Cold Rolled sheets positively affects the paints; accordingly the final-result of the product appears without zigzags or peeled parts. Hence, the paint processes are correlated with the type of sheet used

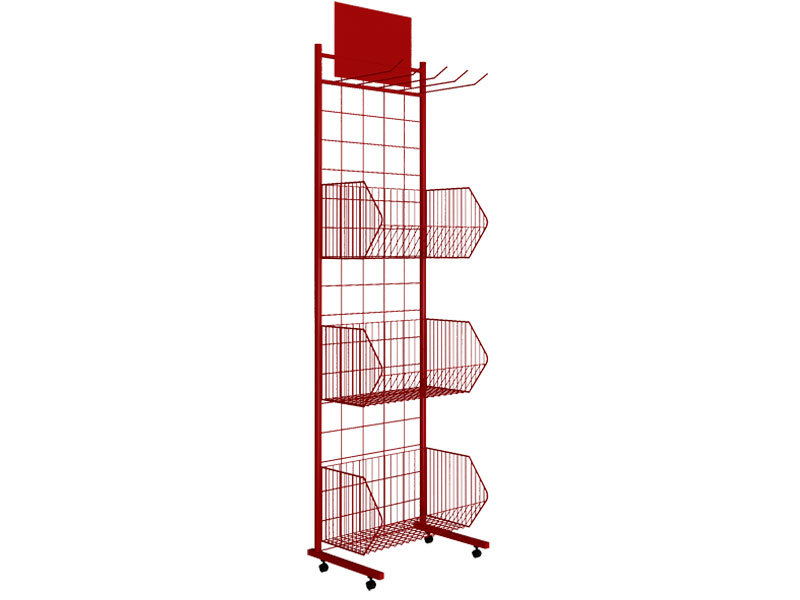

All the previous steps must be done in the paints processes to ensure the best quality of paints that can last for more than 15 years without any defects faced by our customers