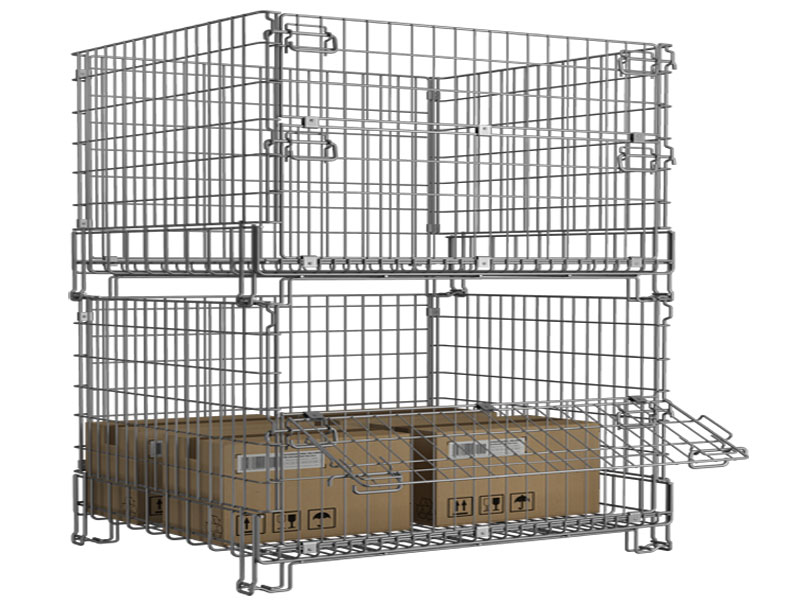

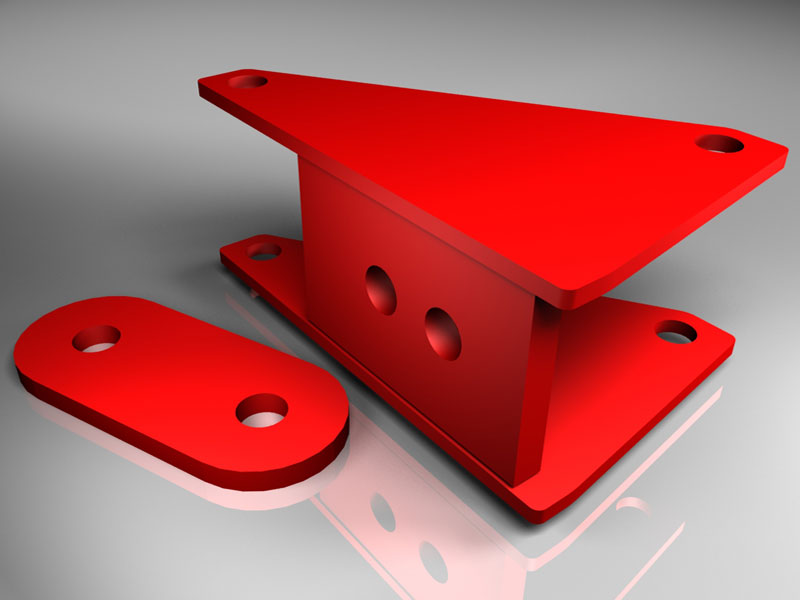

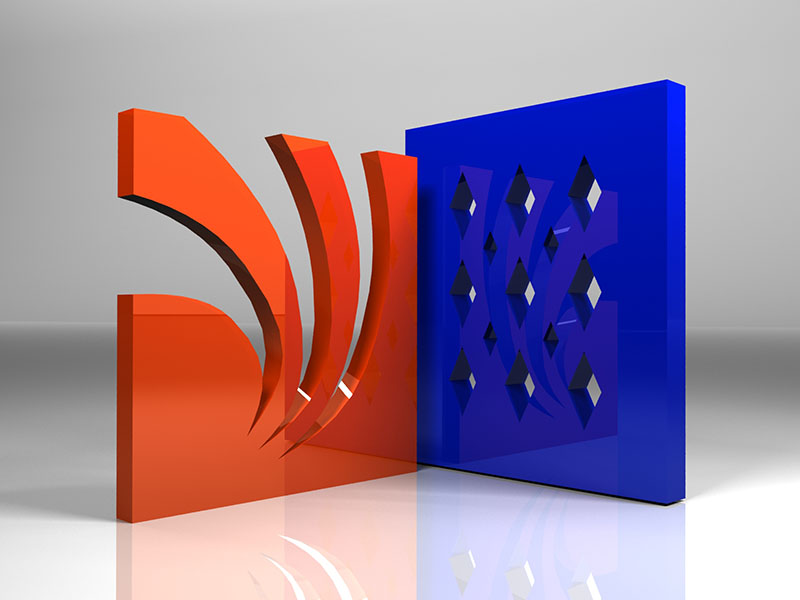

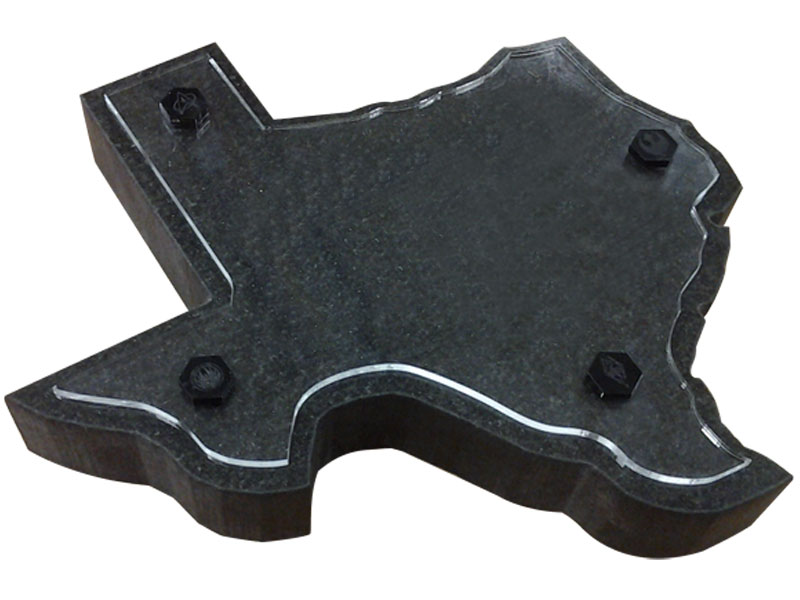

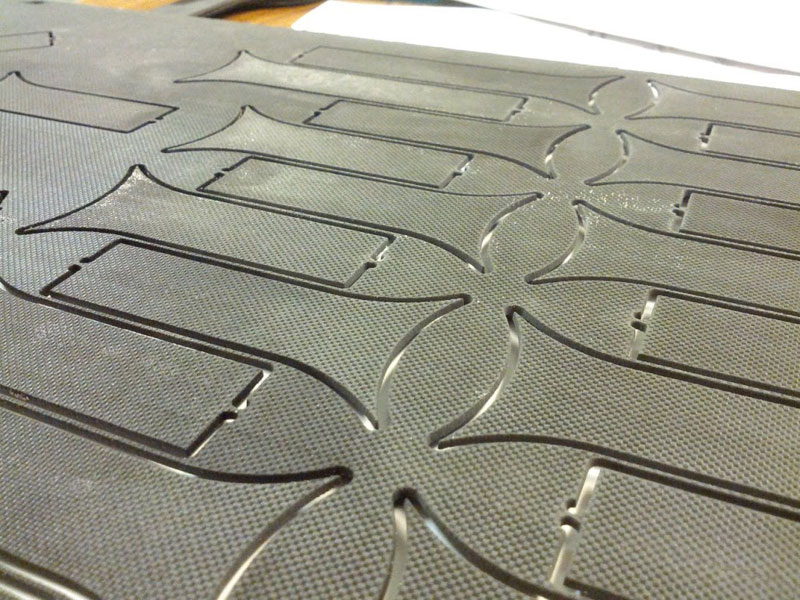

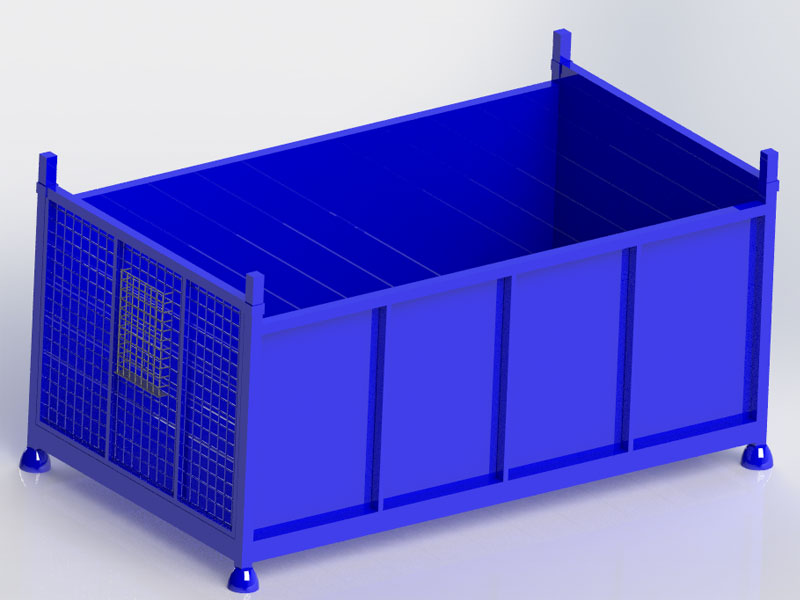

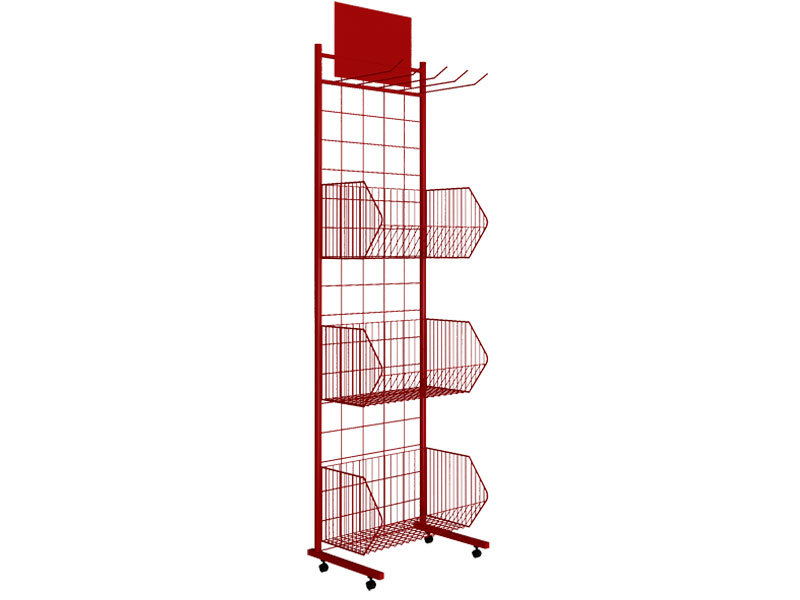

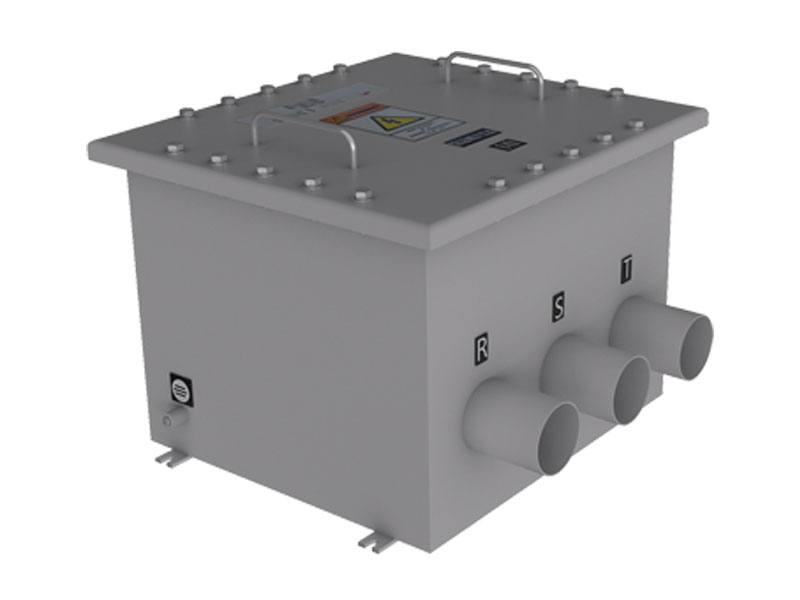

A good paint services through Electrostatic Powder is one of the most difficult services that can be available in the markets with high-level of efficiency, as one of the advantages of our company is its ability to conduct grinding and polishing processes for the product surface before manufacturing, and not after production. Afterwards the product is polished again after plating to ensure the best possible result

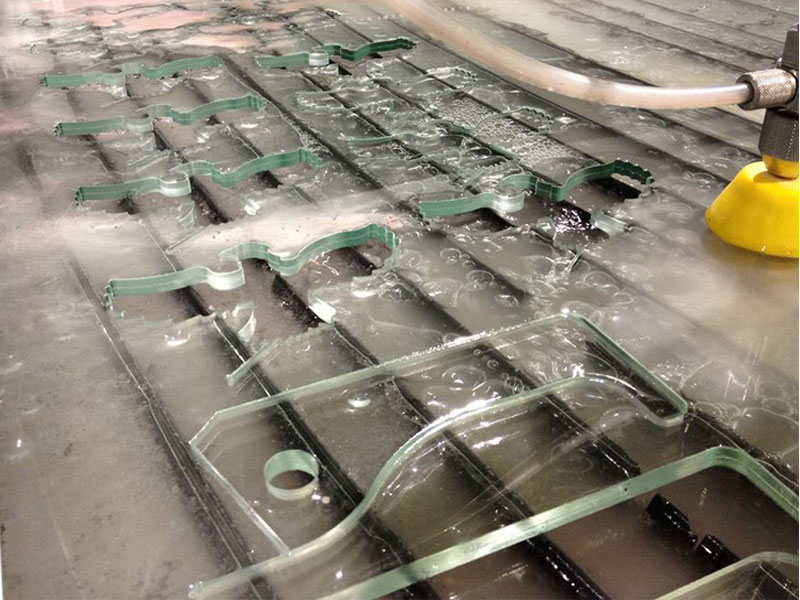

Also plating stages using Electrostatic Powder is done by removing greases and rust, if any, then eliminating the welding places, and cleaning the surface of the product very well. The final step is about plating the product using electrostatic coating powder (nickel and chrome)

Making all of these steps ensures a very high quality of the product coating and makes nickel coating more coherent with the product