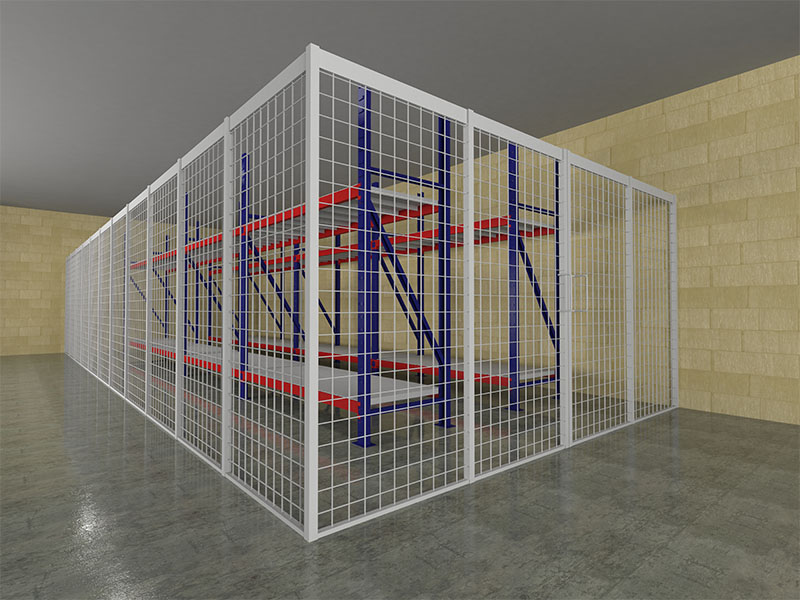

Drive-in-System

Why Drive-in System?

- With drive-in racking; pallets are placed so they can slide backwards on a rail, thus storing them more deeply and creating more space in the warehouse. Drive-in system involves the forklift entering the racking from one side to load or retrieve the pallets which are stored more deeply

- A cost-effective solution, suitable for high-density storage

- Customized designs, with a wide range of heights, available to meet any storage requirements

- Designed specifically to suit pallets and forklifts

- Reduces space, cut costs and holds more loads with its deep lane storage

- Eliminates the need for multiple aisles

- Provides control over entry and exit

- Drive-in pallet rack uses the common entry/exit procedure allowing LIFO, Last-in-First-Out, access to meet your loading and unloading needs

Request a quote

Protducts Categories

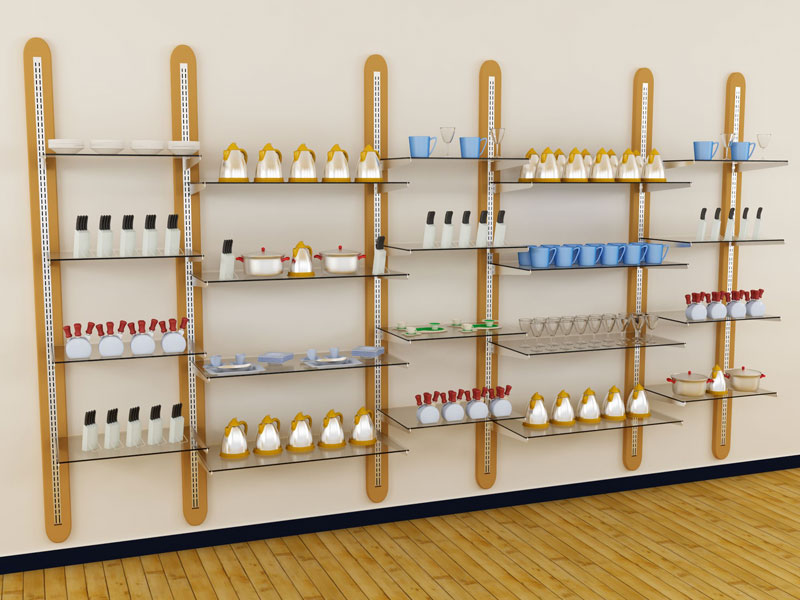

- Shop Display & Fitting Systems

- C Punched Column System

- Cable System

- Connector

- Drawers System

- Stainless Steel Drawers

- Exhibition System

- Four Punched Sides System

- Global System

- Gondola System A

- Gondola System B

- Joker Systems

- Ladder System

- Line System

- Linear system

- Primo System

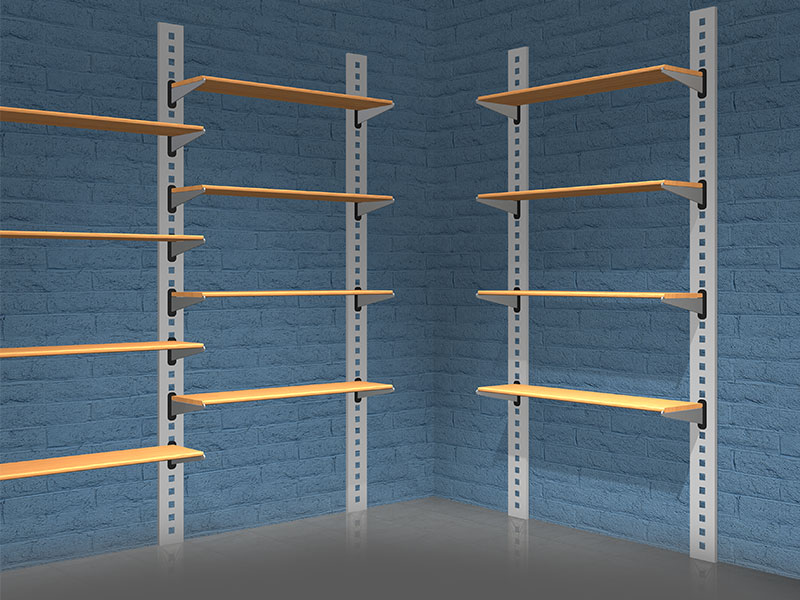

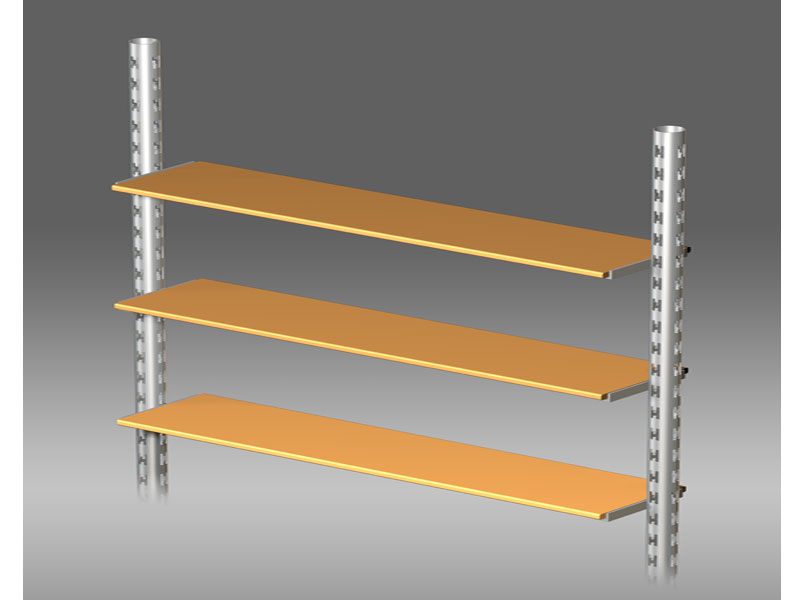

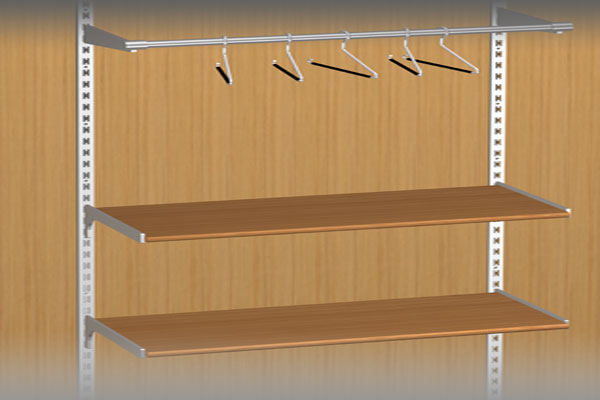

- Punched Wall System

- Rectangular Tubes

- Roto System

- Round System

- Sail System

- Shopping Baskets & Trolleys

- Slat Grid System (Mesh grid)

- Slat Wall System

- Slotted Tube System

- Squared 25 System

- Standard System

- Tubing system

- U Shape System

- Storage & Racking Systems

- Display Stands

- Decorative Stainless Steel Works

- Metal Furniture

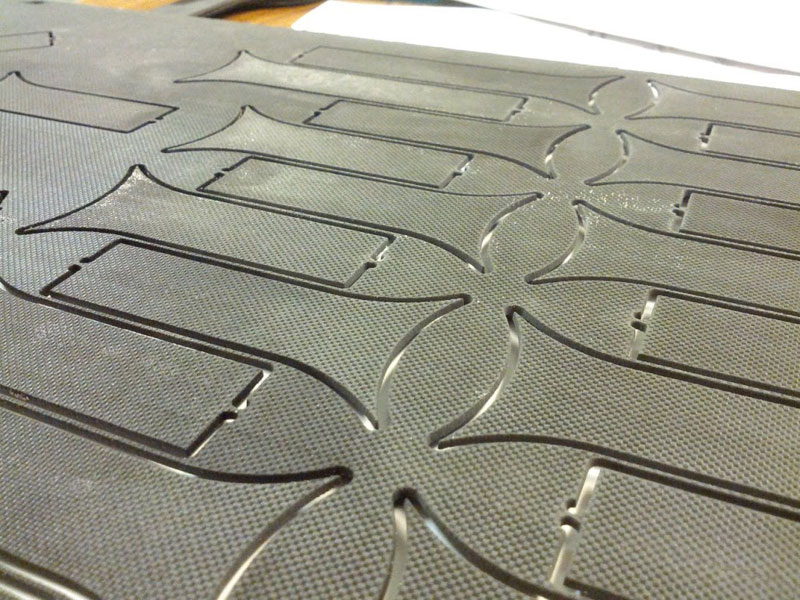

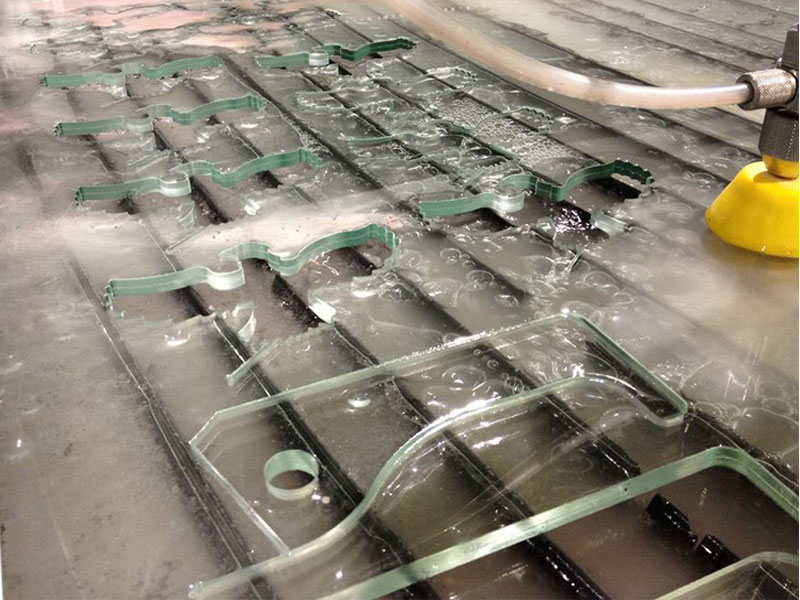

- WaterJet Cutting Applications

- New Customized Solutions

- Flexible Rack system

- Stainless Steel Drawers

- Storage x Gondola System

- British Gondola System

- Mold Table

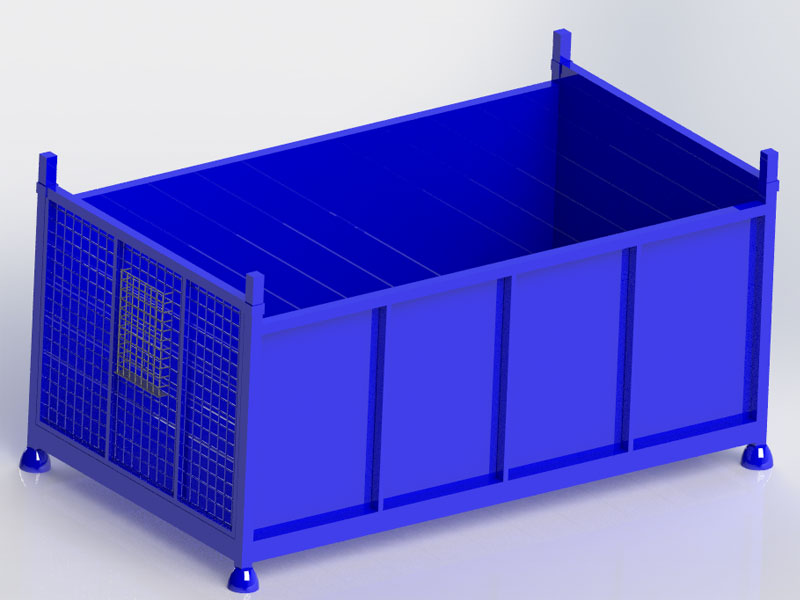

- Trundle for Storing Boxes

- Roll Holder

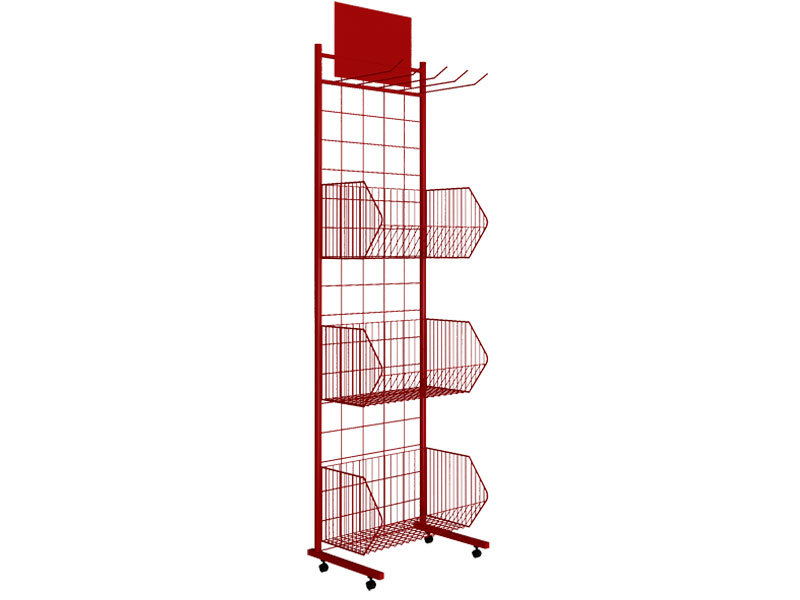

- Snacks Display Stand

- Archive Gondola System

- Punched Gondola

- Gold Plated Columns

- Islamic Design Door

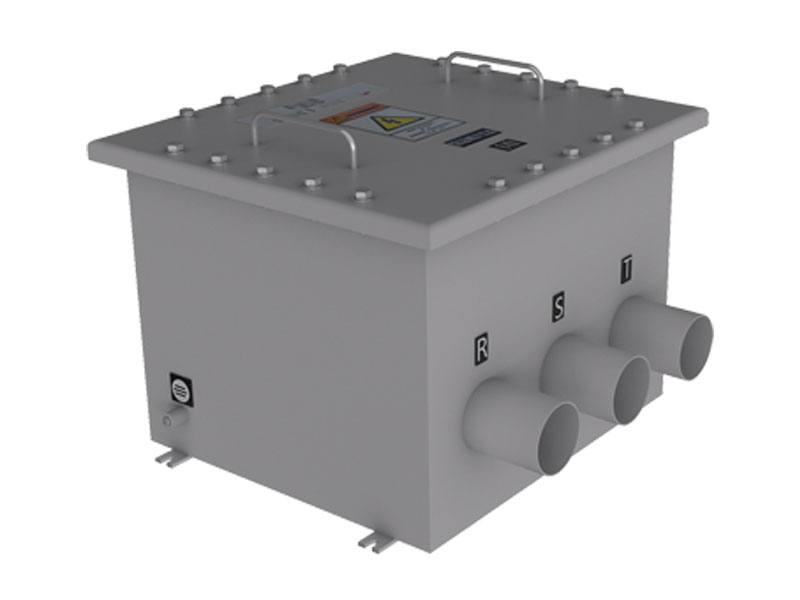

- Protective Electrical Boxes

- Customized Heavy Duty Unit

- Gondola with Wire Bars