Fiber

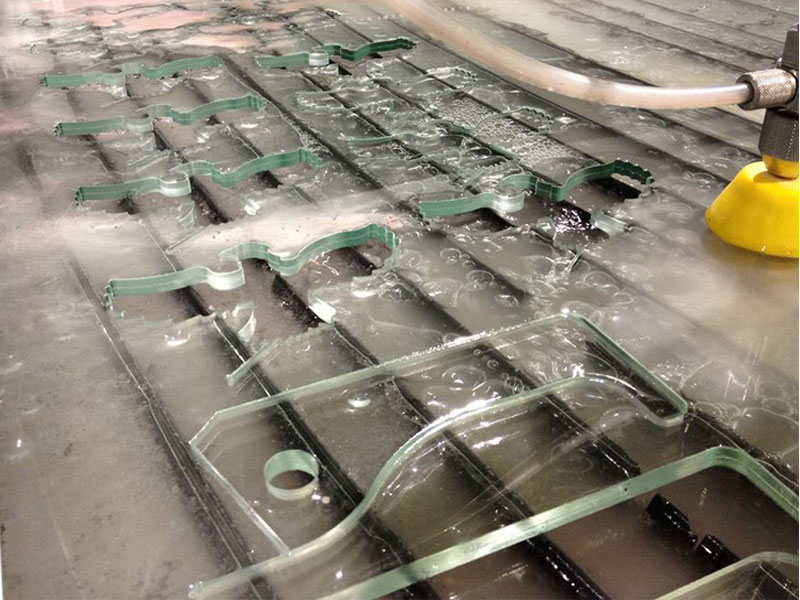

WATERJET (CLASSICA CL 510)

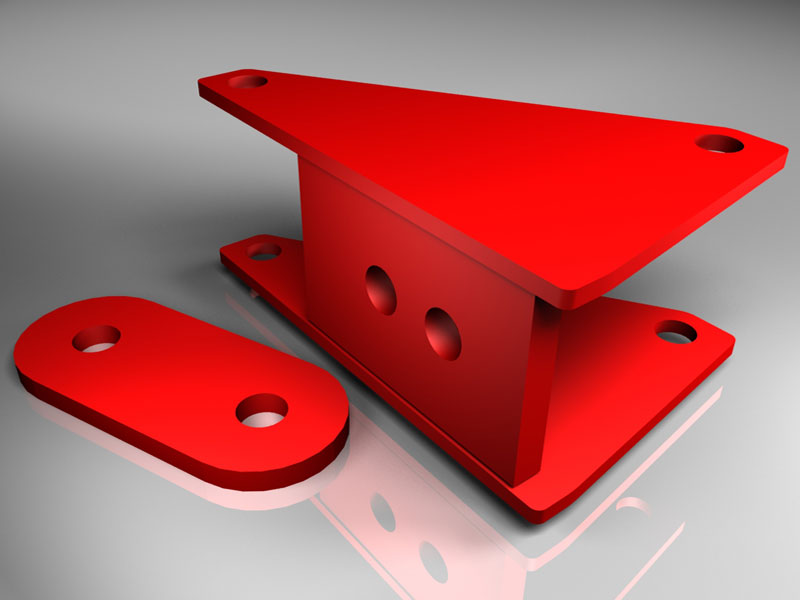

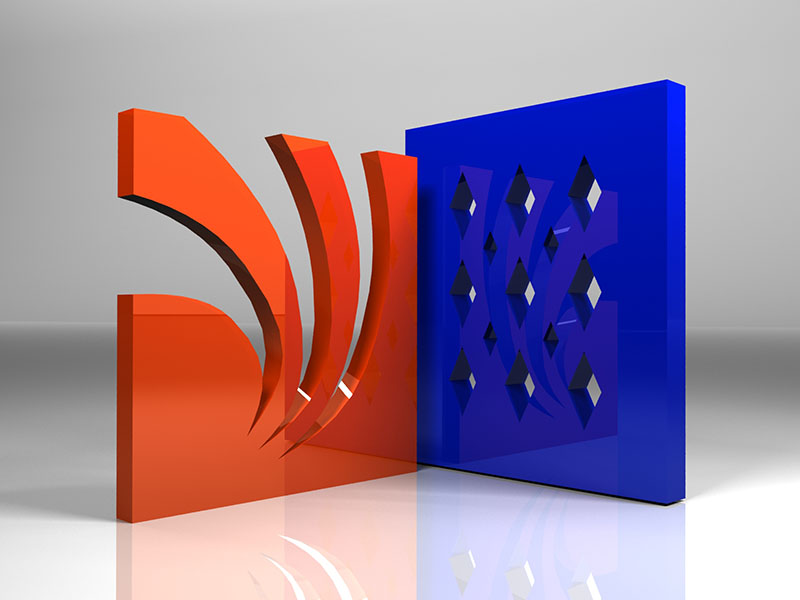

Understanding the importance of beauty and accuracy, ABC For Industries has decided to tackle a new but wide field of industry. WaterJet cutting has proven, only in twenty years, it’s pre-eminence over other cutting machines. Quality is what catches your attention and motivates you to make best use of the WaterJet cutting service we provide

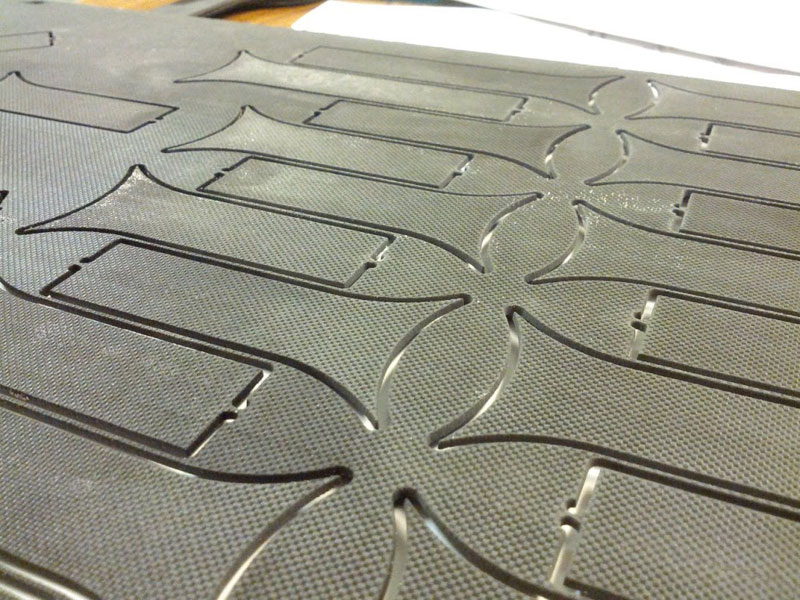

- It is a cutting machine which uses a higher hydraulic power which uses water and an abrasive to cut thick materials. Using AutoCAD, the machine can cut complex geometries and corners with efficiency and speed. The material to be cut is placed on a bed of vertical steel slats, above a big tank of water

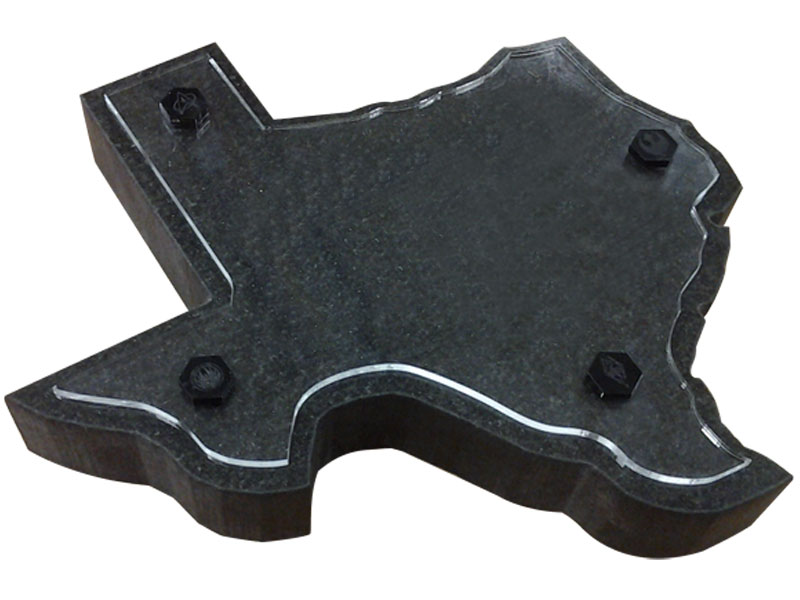

- WaterJet Machine is specialized at cutting various types of materials including, Stainless steel, Steel, Marble, Titanium, Aluminum, Brass, Copper, Tool Steel, Plexiglass, Wood, Plastic, Fiber, Teflon, Glass, Granite, and Ceramic

There are two main steps involved in the WaterJet cutting process as follows:

- First: the high pressure pump generally pressurizes normal tap water at pressure level about (60,000 psi)/ (4137 bar) to produce the energy required for cutting

- Second: water is then focused into a small stone orifice to form an intense cutting stream. The stream moves at a velocity of up to 4 times the speed of a sound, depending on how the water pressure is exerted. The process is applicable to both water only and abrasive jets. For abrasive cutting applications, abrasive garnet is fed into the abrasive mixing chamber, which is part of the cutting head body to produce a coherent and an extremely energetic abrasive jet stream

- Time: Once you have the design and the dimensions, the machine will cut typically and accurately as your design. Moreover, you can put more than one sheet to be cut at once

- Variety: The machine can cut into a wide variety of mediums including : Aluminum, Bonded metals, Carbon Fiber, Carbon Steel, Composites, Exotic Metals, Fiberglass, Glass, Marble, Plastics, Stainless Steel, stone, Thermoplastics, Titanium, Tool Steel and other

- Strength: The machine can cut until 150 mm

- Quality: The machine uses water to cut, which does not leave heat affected zones, or change the physical properties of the material

- Besides, the metal will be finely cut, which needs no other finishing steps

- WaterJet cuts metal and non-metal materials by the Force of water and thus preserves the characteristics of the material required to be cut, as water maintains the characteristics of materials unlike laser cutting. Moreover, water cutting can cut up to 1.5 m x 3 m size and to 15cm thickness

- Cutting area dimension: (x) 3000 mm x (Y) 1600 mm x (Z) 160 mm

- Cutting thickness: Cuts up to 150 mm thickness

- Cutting Speed: from 0-20 m/min

- High Accuracy and versatility: the machine is capable of cutting any curve with high accuracy and versatility.

- Two Cutting Heads: the machine has two cutting heads to decrease the production time to 50%. Also, waterJet machine can cut more than one sheet at once

- Thick Materials Cutting: the machine can cut till 150 mm thickness

- Types of Materials: the machine can cut into a wide variety of mediums with only one tool such as: aluminum, bonded metals, carbon fiber, carbon steel, composites, exotic metals, fiber glass, glass, marble, plastics, stainless steel, stone, thermoplastics, titanium, and tool steel

- High Surface Finish: the metal will be finely cut with high surface finish, which needs no other finishing steps.

- Touch Screen CNC

- The numeric control is capable of automatically controlling operative functions with a high quality and precision by means of a graphic simulation

- A membrane keyboard, a color monitor and an Ethernet network card are present

- The design of the required cutting can be inserted to CNC by USB flash memory in a form of a CAD file format such as, AutoCAD file

“Pressure intensifier (KMT JETINE JL -1 50)”

- High Pressure Water System: the high pressure water system is the heart of the water jet system. Water is pressurized and continuously delivered to the cutting head. As water passes through a tiny hole in the orifice of most materials, water pressure is converted to water capable of cutting

- Technical data

- Max. Single Orifice Diameter 0.36mm

- Electrical (3 phases / 380 volt / 69 Amp.)

- Dimensions (2,006 x 914 x 1.183) mm

- Weight (816 kg)

- Water Consumption 3.8 liter/min, gal/min

- Max. water pressure 60,000 (psi) / 4137 (bar)

- Power 50 HP / 37 KW

The machine can facilitate your work in many fields of industry. It can be used to make a final product, like art works, or it can be a step in your project, like machine building

Many huge industries already make use of WaterJet cutting machine, like:

- Marine & Shipbuilding

- Art & Design

- Oil & Gas

- Rail

- Metal industry

- Building Industry

- Interiors and Decorations

- Glass, Stone & Ceramics Industry

- Plastic Industry

- Food Stuffs Industry

- Wood Working Industry

- Automotive Industry

- Electrical Industry

- Aerospace

- Precision Engineering

- Electronics Industry

- Retail

- Glass Cutting

- OEMs

- Catering

- Automotive

- Architecture

- Medical Engineering

- Sign Makers

- Agriculture

- Construction

- Design services

ABC For Industries is offering its clients the design facility and support for the required WaterJet application regarding their needs. Also modifying data or AutoCAD files that has been made by the customer is available for proper cutting

- Raw Material Support

ABC For Industries has the facility to provide the client with raw material that fits the design for the required WaterJet application regarding the needs of the client

- Material Finishing & Painting service

ABC For Industries is offering the service of finishing and painting the final products regarding the needs of the client such as electroplating, powder coating and many other forms of finishing

- Transportation and delivery service

ABC For Industries has the facility to get raw materials or deliver the final work to the required location regarding the needs of the client

- Other Services

- We accept any AutoCAD file, or a sample of the produce you want to cut

- We can cut numerous metals and material

- Our WaterJet machine has two heads which reduplicates production

- The machine has the ability to cut until 150 mm thickness*160 cm width*3 meters length

- We commit ourselves to delivery time and handing you a high quality product

ABC For Industries has dealt with many reputable multinational corporations that have trusted our name and its capabilities. Listed below are some of our customers

Request a quote

Protducts Categories

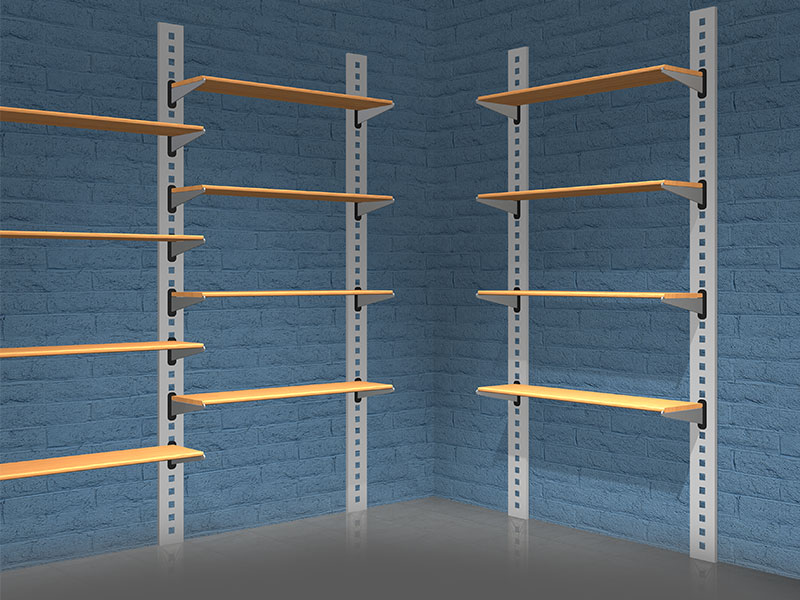

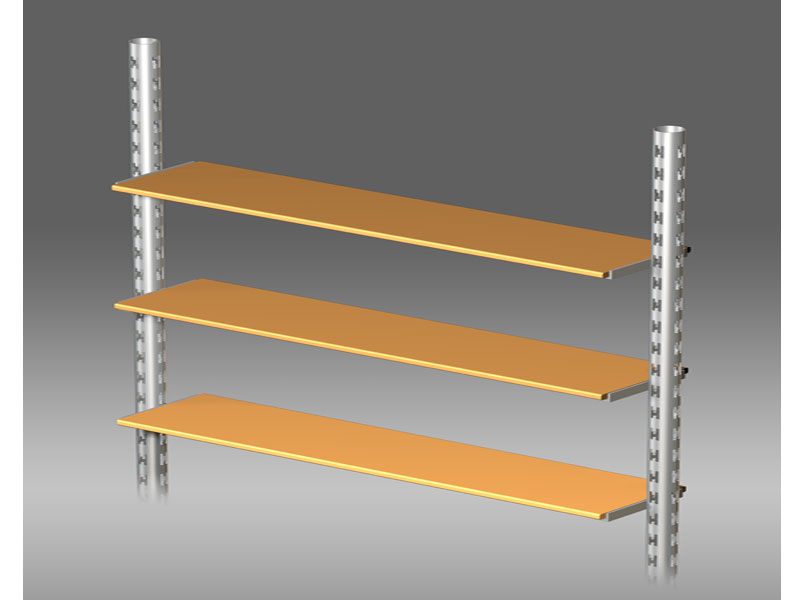

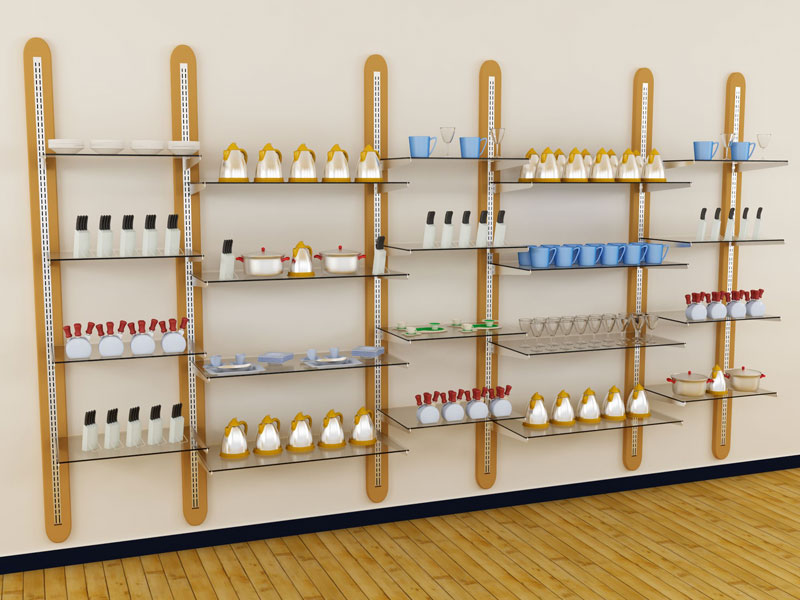

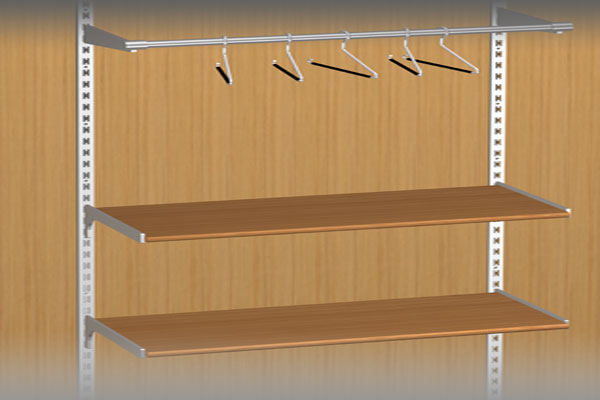

- Shop Display & Fitting Systems

- C Punched Column System

- Cable System

- Connector

- Drawers System

- Stainless Steel Drawers

- Exhibition System

- Four Punched Sides System

- Global System

- Gondola System A

- Gondola System B

- Joker Systems

- Ladder System

- Line System

- Linear system

- Primo System

- Punched Wall System

- Rectangular Tubes

- Roto System

- Round System

- Sail System

- Shopping Baskets & Trolleys

- Slat Grid System (Mesh grid)

- Slat Wall System

- Slotted Tube System

- Squared 25 System

- Standard System

- Tubing system

- U Shape System

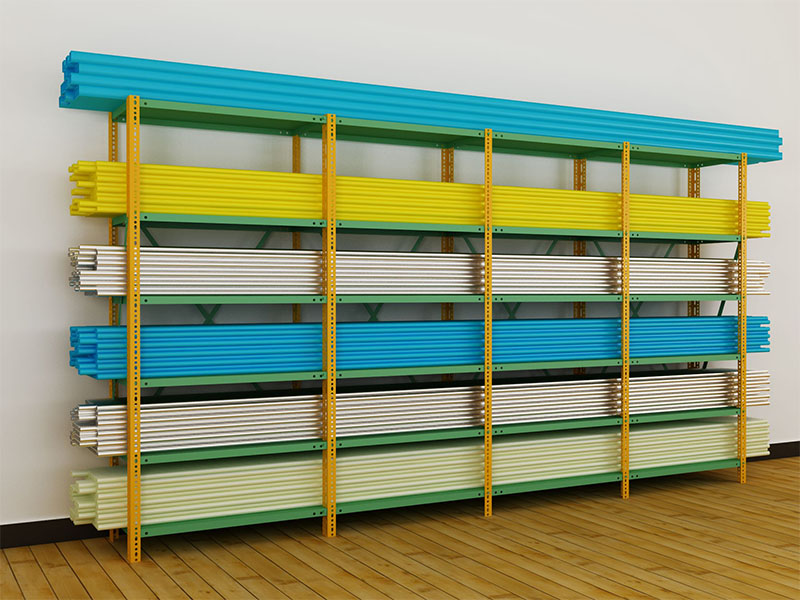

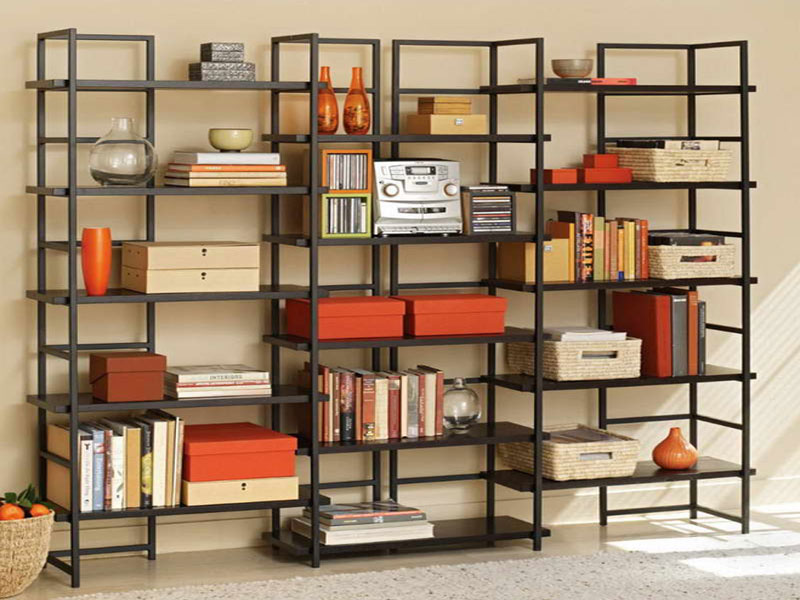

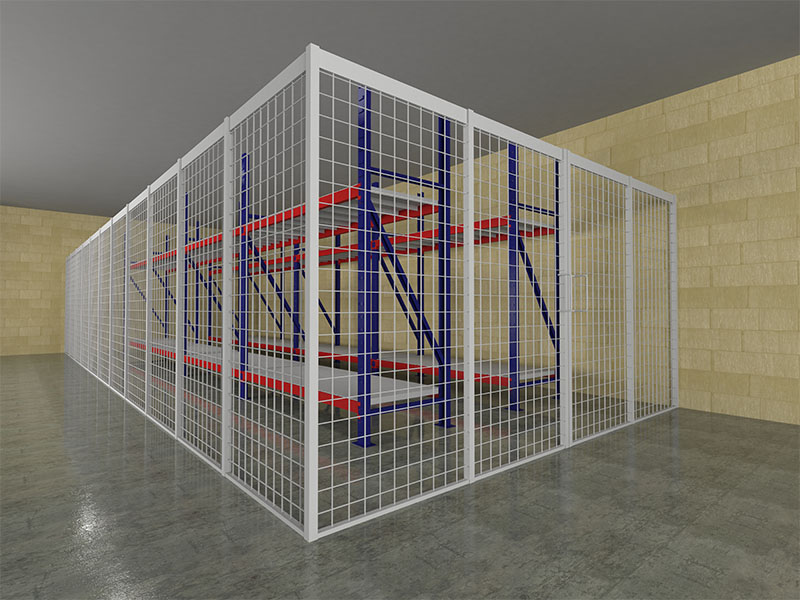

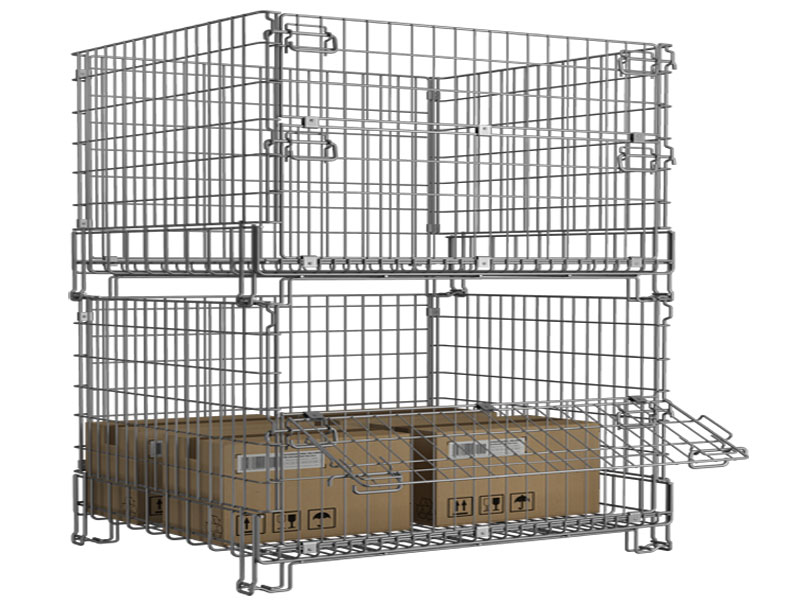

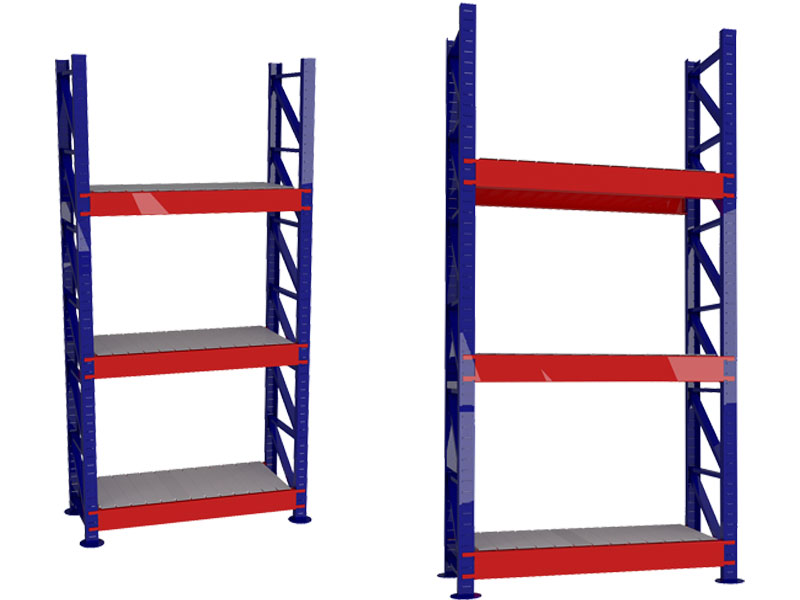

- Storage & Racking Systems

- Display Stands

- Decorative Stainless Steel Works

- Metal Furniture

- WaterJet Cutting Applications

- New Customized Solutions

- Flexible Rack system

- Stainless Steel Drawers

- Storage x Gondola System

- British Gondola System

- Mold Table

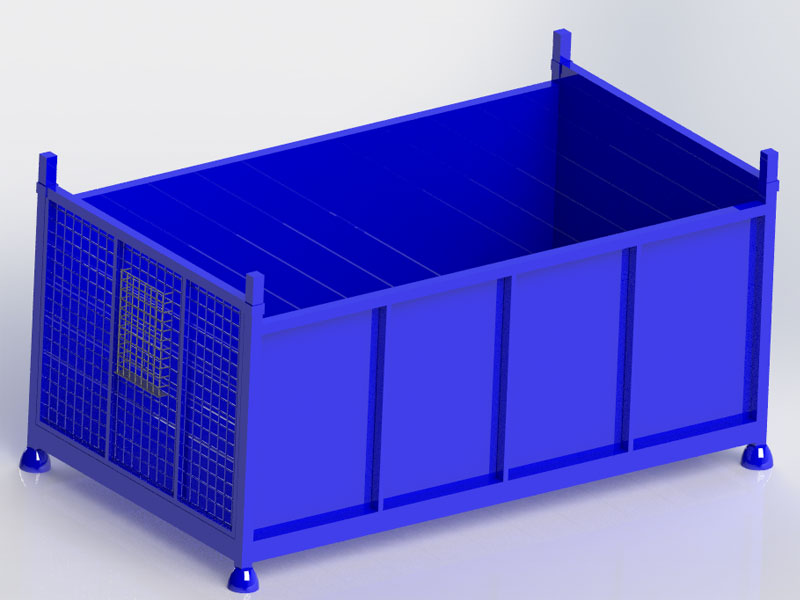

- Trundle for Storing Boxes

- Roll Holder

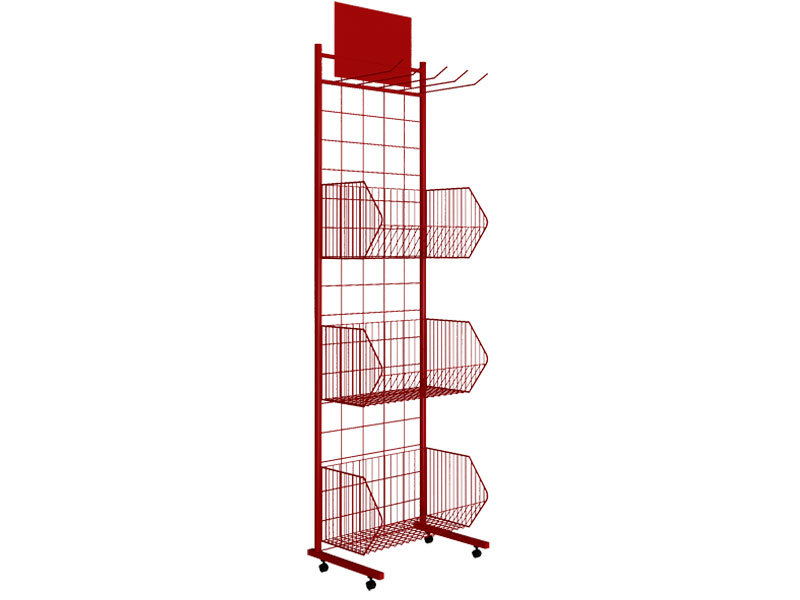

- Snacks Display Stand

- Archive Gondola System

- Punched Gondola

- Gold Plated Columns

- Islamic Design Door

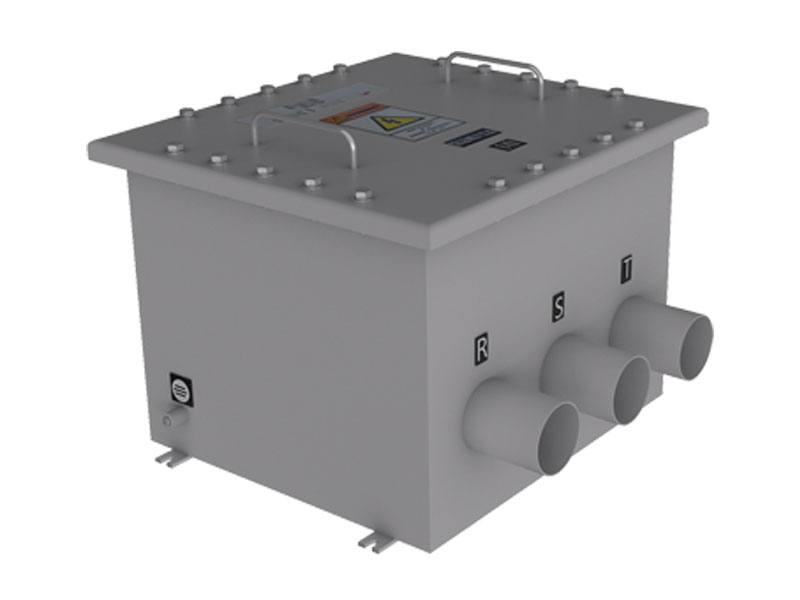

- Protective Electrical Boxes

- Customized Heavy Duty Unit

- Gondola with Wire Bars